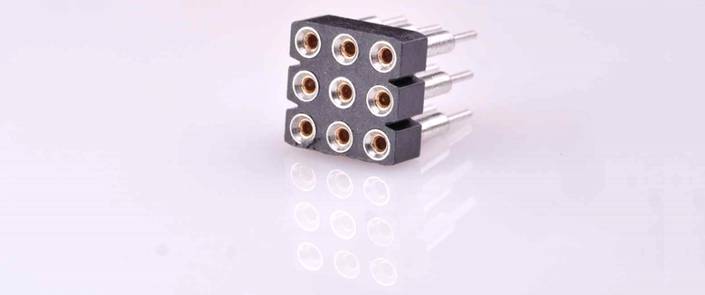

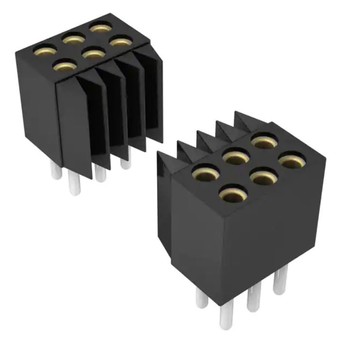

PRECI-DIP .05” (1.27MM) PITCH TRIPLE ROW HEADER AND TRIPLE ROW SOCKET RECEPTACLES

PRECI-DIP .05” pitch triple row headers connector offers higher density compared to a single or double row connector with a standard .01” pitch. It provides a greater number of contact points or pins within the same physical space, allowing for more connections or signals to be transmitted simultaneously.

This triple row package, on a .005" (1,27 mm) grid, is available from 9 to 150 position configurations (ordered in increments of 3.).

The 854 & 855 series connectors are RoHS compliant. The Receptacle Sleeve of the 855 series is plated with Tin over Nickel and the Contact area is plated with 30’µm or flash gold. Headers are commonly plated with pure matte tin or 10’µm gold, for headers a selective plating can be quoted to customer specification.

PRECI-DIP offer straight and right-angle configuration for headers and receptacle. According to available space, PCB layout, and orientation of the connections

Features and Benefits

- Higher Density: Triple-row headers allow for a higher density of connections in a limited space. With three rows of pins or sockets, you can achieve greater connectivity without increasing the overall size of the connector. This is particularly beneficial in applications where space is at a premium.

- Enhanced Flexibility: Triple-row headers offer greater flexibility in terms of design and functionality. They provide more options for routing signals and power lines, allowing for complex circuit arrangements. This flexibility is particularly advantageous in applications requiring intricate PCB layouts or multi-board connections.

- High Precision: Contacts are manufactured using Swiss high-precision machining processes, resulting in contacts with very tight tolerances, ensuring reliable electrical connections.

- Longevity: Machined contacts are durable and have a long field life, as they are made from high-performance materials that can withstand repeated use and harsh environmental conditions.

Applications

- Industrial Applications: In industrial settings, triple-row headers can facilitate the interconnection of various modules, controllers, or sensor arrays. Their high connection density and robust design make them suitable for demanding environments that require reliable and secure connections.

- Telecommunications and Networking: Triple-row headers are useful in telecommunications and networking equipment, where numerous data lines and interfaces need to be accommodated. They enable efficient routing and management of signals within network switches, routers, servers, or telecommunications infrastructure.

- Consumer Electronics: With the miniaturization trend in consumer electronics, fine-pitch headers enable more functionality to be integrated into smaller devices. They can support compact designs in tablets, wearable devices, and other portable gadgets.

- Medical: Medical devices often require numerous connections to transmit data, power, and control signals. Triple-row headers provide a higher connection density, allowing more signals to be accommodated within a limited space. This is particularly beneficial in compact medical devices or systems where size and weight are critical factors.