Industry and automation rely on varied and pinpointed connector concepts

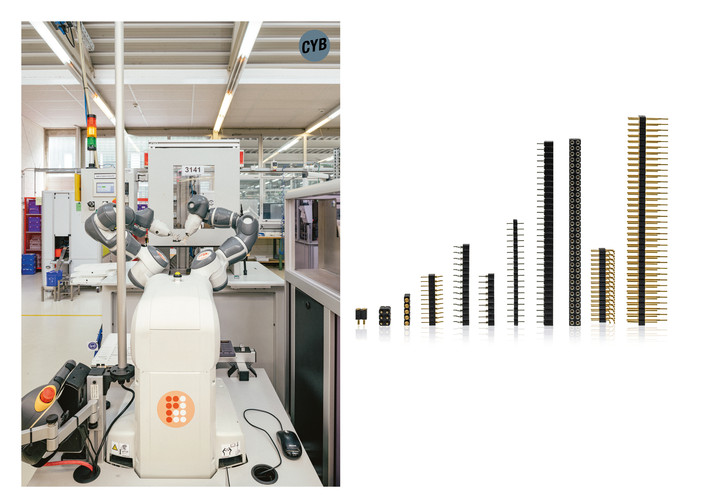

PRECI-DIP is a major provider of standard and customized connectors for this challenging industrial market where harsh environment requirements are commonplace. To meet these challenges, we have developed robust designs and dedicated fully automated assembly lines that ensure long-lasting durability and quality. Applications developed include flowmeters, industrial motors, industrial control modules, robotics, etc. Our solutions are embedded in the domain of industry 4.0. Staying ahead of the advances in automation technologies is one of PRECI-DIP’s core competencies. Manufacturers seek to build advanced higher density packaging technologies with faster and smaller products. We anticipate these developments to meet the demands of the industry, for instance, by providing our products with low contact resistance and extremely high current density embedded in a reliable design specifically engineered for high mating frequencies.

Ensuring optimal performance day in and day out. Custom-made connector solutions help power industrial automation.

A full range of board-to-board connectors, from one to three rows of contacts, with

various board terminations (SMT, tail, press-fit) using various pitch configurations (1 mm,

1,27 mm, 2 mm, 2,54 mm,4mm). These connectors are integrated within many industrial applications

for power and signal connections.

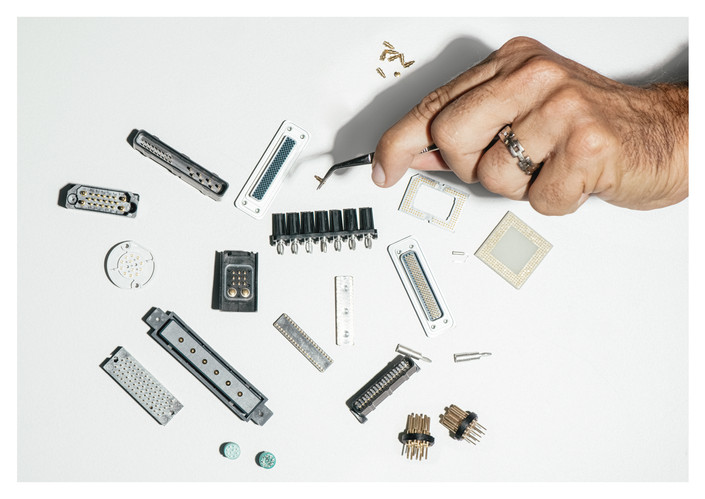

Delivering a wide variety of custom-made solutions. With top materials. With advanced designs. And with a fully integrated production process.

Custom Design Is Creativity Realized

Our design teams have vast experience in material sciences, electrical engineering, process engineering, and machine building. We apply this know-how to many diverse applications and industries, utilizing an agile and sustainable approach. We use state-of-the-art tools for FEA, mold-flow analysis, and product performance simulation. These tools provide for rapid and reliable development, problem solving, validation, and, ultimately, premier solution fulfillment.