Turnkey and reliable ideas for medical interconnect devices

PRECI-DIP has developed breakthrough innovations in medical interconnect technologies, including applications for handheld monitoring devices, hearing aids, personal glucose monitors, defibrillators, X-ray and ultrasound scanners, and many others We have also developed and produced lead-free contacts, meeting RoHS-3 requirements, using advanced materials. Our production facilities meet stringent cleanliness requirements, fulfilling our commitment to developing and providing the best in medical market solutions.

Safety comes first thanks to precise, reliable connectors for pacemaker applications.

Micro socket shaped with a 0.66 mm square barrel mating with a 0.20 mm pin on the cardiac pacemaker’s electronic board. These sockets are assembled and controlled utilizing our proprietary designed/built manufacturing system. Cleanliness of each part is optically controlled, automatically.

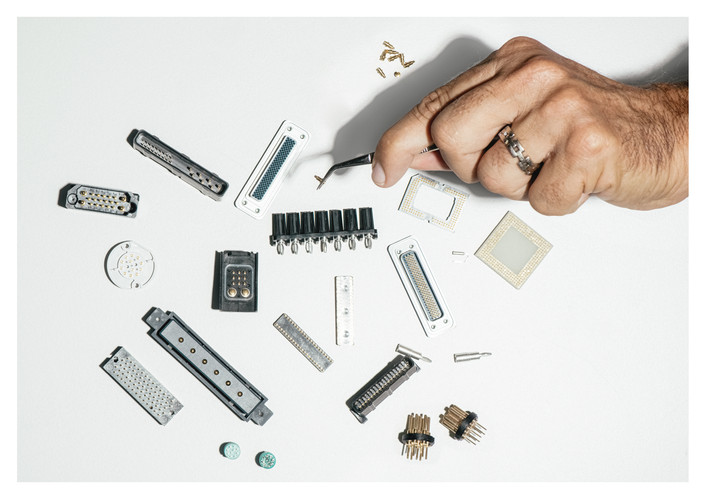

Delivering a wide variety of custom-made solutions. With top materials. With advanced designs. And with a fully integrated production process.

Custom Design Is Creativity Realized

Our design teams have vast experience in material sciences, electrical engineering, process engineering, and machine building. We apply this know-how to many diverse applications and industries, utilizing an agile and sustainable approach. We use state-of-the-art tools for FEA, mold-flow analysis, and product performance simulation. These tools provide for rapid and reliable development, problem solving, validation, and, ultimately, premier solution fulfillment.